USE CASES

Kiln Drying Optimization

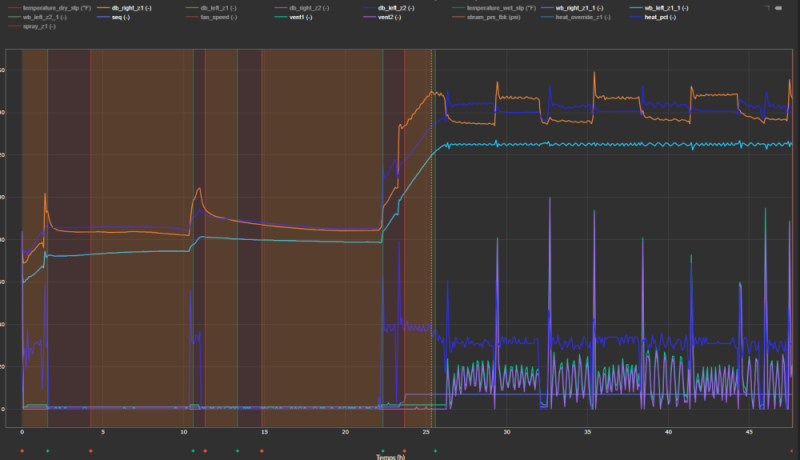

Moisture content plates anomaly

Anomaly

The four moisture content plates returning the same percentage and/or a communication error occurred.

Potential

consequences

The end of the drying will not be defined in an appropriate way due to the wrong value of the mean moisture content. And this will lead to an over\under dried batch.

Corrective

action

Our experts warned the client and the company responsible of the data collection to fix the issue. The plates worked fine after this (see graph).

Humidity evacuation anomaly

Anomaly

One of the wet bulb sensor’s temperature reading is giving a abnormally high value compared to the sensors.

Potential

consequences

The average of the web bulb temperature is higher than the set-point so the vents began to evacuate the humidity while the climate is dry.

Corrective

action

Our experts diagnosed the anomaly and suggested the client change the cotton of the wet bulb sensor which returned the readings to normal.

Kiln sudden stop anomaly

Anomaly

Once the drying have been started, the fan speed and the heat went down to 0. This anomaly occurred at the end day of Friday

Potential

consequences

The drying is stopped during the weekend without noticing. The client could loose two days of drying time.

Corrective

action

Our experts noticed the alarm using our notification system and report it to the mill. The operator returned to the mill and restarted the kiln.